Stainless steel is one of the materials that is commonly used in the field of construction. It is a versatile material that has many advantages. It is durable, long-lasting and good looking. Due to its versatility, there are many stainless steel fabrication techniques that are carried out by steelworks in Singapore. Each fabrication process has its own pros and cons, so before choosing a specific type it is important to carry out proper research of all these processes.

Although stainless steel is versatile and durable and has high strength, it is malleable enough that it can be folded, bent, welded, machined, spun and deep drawn. Especially, the steelworks companies will carry out fabrication processes such as welding, machining and work hardening. Notably, the work hardening process of this material will increase its magnetism. The grades of stainless steel will relatively higher work hardening rates will possess a high magnetic capacity. Stainless steel undergoes great deformation.

Machining stainless steel can be a really complex process due to several reasons such as the high possibilities of getting chipped. So, when it comes to machining stainless steel, the steelworks companies will follow a set of suggestions that are shared by the experts in the industry. These tips will help handle the machining process of the alloy without any difficulty. These tips are given below,

These tips will really be helpful in the steel machining process and reduce the complexity that is actually involved during this type of fabrication. To overcome the limitations of the process of some specific types of stainless steel, there are companies that incorporate the exclusive steel melting techniques.

The process of work hardening strengthens the material via deformation. Similar to the other types of steel, even stainless steel will work harden quickly. The exact rate of work hardening depends on the grade of the alloy that is subjected to the process. Notably, the austenitic family of this allow has a relatively higher hardening rate than that of carbon steel. And, it is a frequently used grade of stainless steel in the fabrication process in Singapore.

It is helpful to match the grade of this alloy with the work hardening treatment depending on the suitable option for it. Usually, the austenitic stainless steel can be hardened only via cold working, which is actually a thermal treatment process that is better applied to the other grades of stainless steel including martensitic series. The series of this alloy that is benefited the most from the work hardening applications are the martensitic and austenitic series as the ferrite stainless steel yields relatively lower work hardening rates.

Most types of stainless steel are possible to weld but the degree at which the welding can be done depends on the grade of the alloy. All the austenitic stainless steel series except for grade 303 can be welded. But the group is prone to inter-granular corrosion and sensitization on thicker products. So, low carbon content grades like 304L and 316L are preferred for welding thick materials. Even stabilized grades like Grade 347 are effective for welding purposes.

Martensitic grades are good options when it comes to welding but these are prone to cracking. In order to reduce the cracks, experts in Singapore recommend pre-heat and post-heat procedures or use of supplementary austenitic filter rods. There are ferritic stainless steel grades that are less suitable for welding. However, grade 409 can be used to select projects. Still, there are issues such as low ductility, high grain growth and sensitization. The duplex grade has low thermal expansion and is efficient for welding purposes. The grade 2205 is highly suitable for such applications as it has higher nickel content that improves strength, corrosion resistance and ductility.

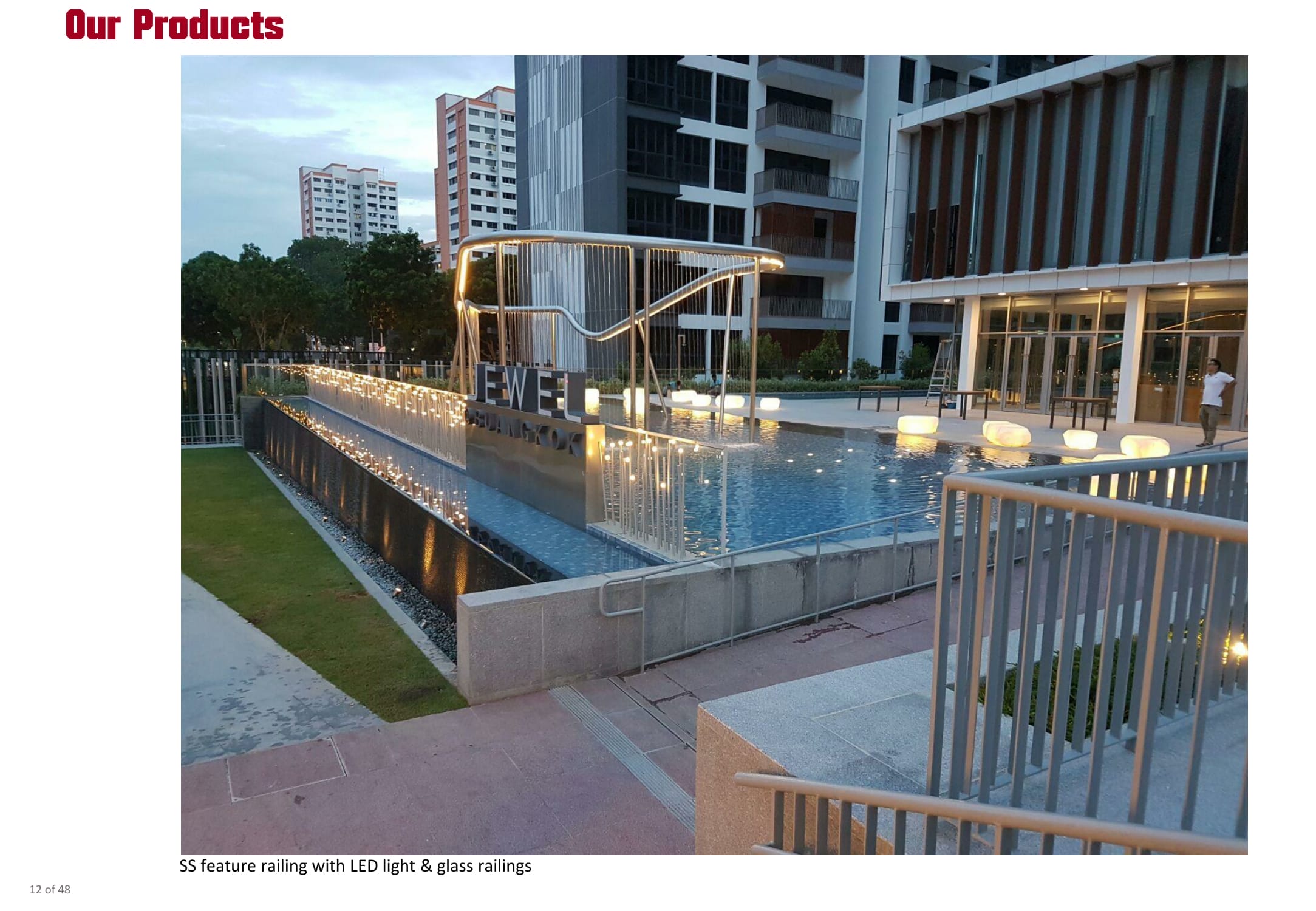

Brooklynz Stainless Steel Pte Ltd is a specialized tier 1 stainless steel fabricators involved in the design, fabrication & installation of customized stainless steel products for construction projects.

Brooklynz provides an end to end solution for all types of stainless steel works across all sectors that employ heavy steel structures.